The spraying process plays an extremely important role in the production process. Therefore, to better integrate the sandblasting, painting, and drying processes and improve production efficiency, it is appropriate to choose battery powered rail electric trolley.

Project Overview

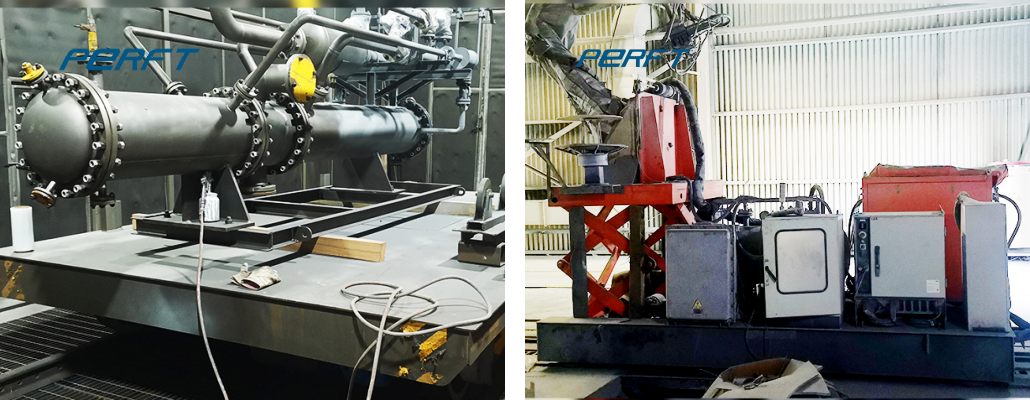

Recently, American customer consulted us about how to use our battery powered rail guided transfer trolley in the abrasive blasting booth. Through our detailed introduction, he had a deep understanding of this battery operated transfer trolley and placed an order with us.

Custom Rail Guided Transfer Cart

First of all, it is very important to choose a suitable electric transporter trolley. You can choose according to the working environment and workpiece requirements. Generally speaking, we can consider the following points:

- Carrying capacity: Choose an electric transporter with a corresponding carrying capacity according to the weight of the workpiece to ensure the safety and stability of the work.

- Rail layout: We will customize transfer trolley according to the layout of your production line and the requirements of the spraying process. Ensure that the track layout of battery operated transfer trolley matches the layout of the entire spraying line, and can run freely on the track.

- Raw material selection: Perfect uses rail guided transfer trolley materials with durable and corrosion-resistant characteristics to ensure long-term use and stability.

- Control painting parameters: By reasonably adjusting the painting parameters of electric transfer trolley, such as painting pressure, painting speed, and painting distance, ensure that the paint is evenly sprayed and does not pill or peel off.

Technical Parameters of Rail Transfer Cart

|

Model |

BXC-2t | BXC-20t | BXC-50t | BXC-100t |

BXC-150t |

|

Rated Load(t) |

2 | 20 | 50 | 100 |

150 |

|

Length(L) |

2000 | 4000 | 5500 | 6500 |

10000 |

|

Width(W) |

1500 | 2200 | 2500 | 2800 | 3000 |

|

Height(H) |

450 | 550 | 650 | 900 |

1200 |

|

Wheel Base(mm) |

1200 | 2800 | 4200 | 4900 | 7000 |

|

Rail Inner Gauge(mm) |

1200 | 1435 | 1435 | 200 |

2000 |

|

Wheel Diameter (mm) |

Ф270 | Ф350 | Ф500 | Ф600 | Ф600 |

|

Running Speed (m/min) |

0-25 | 0-20 | 0-20 | 0-20 |

0-18 |

|

Motor Power(kW) |

1 | 2.2 | 5 | 10 | 15 |

|

Battery Capacity |

180 | 180 | 330 | 440 |

600 |

|

Battery Voltage |

24 | 48 | 48 | 72 | 72 |

|

Running Time When Full Load |

4.32 | 4 | 3.3 | 3.2 |

2.9 |

|

Running Distance for One Charge(km) |

6.5 | 4.8 | 4 | 3.8 | 3.2 |

|

Recommended Rail Model |

P15 | P24 | P43 | QU100 |

QU100 |

Introduction of Battery Material Handling Cart

Battery powered transfer cart body is welded from steel plates and is equipped with two control modes: remote control and wireless remote control. It has strong braking force, which is divided into electromagnetic and mechanical wheel brakes.

When we transport large tonnage of materials, we are worried that the materials will pile up and we cannot see whether there are people or objects suddenly appearing in front. Therefore, rail guided transfer trolley is equipped with a sensing system, which will automatically stop when people or obstacles appear. It can travel along a fixed track, avoiding inaccurate transportation caused by manual operation or other factors, and improving production efficiency and quality.

In summary, by rationally selecting rail transfer trolleys and scientifically arranging the sandblasting, painting, and drying processes, we can improve production efficiency and ensure the smooth operation of the spraying line. The use of battery powered rail transfer carts can not only improve work safety but also improve production efficiency, making the entire spraying line more efficient and stable. For more cases, you can see this article — Thailand Transfer Cart On Wheel 16 Ton.

40T Rail Guided Transfer Trolley Video

Rail electric transfer cart shown in the video is designed specifically for the sandblasting room! It is carrying a 40-ton pressure vessel to operate in the confined space of the paint spraying room and is a model of strength and durability.