Electric transfer carts on rails for motor driven foundry industry applications are powered by battery. The battery is installed inside the cart. The main reason for using battery power is to consider long-distance transportation.

Load capacity: 1-500t customized

Dimension: Can be customized

Power supply: Battery/Cable/Busbar/Rail optional

Control system: PLC system, remote control or fixed pendant

Running speed:20-30m/min

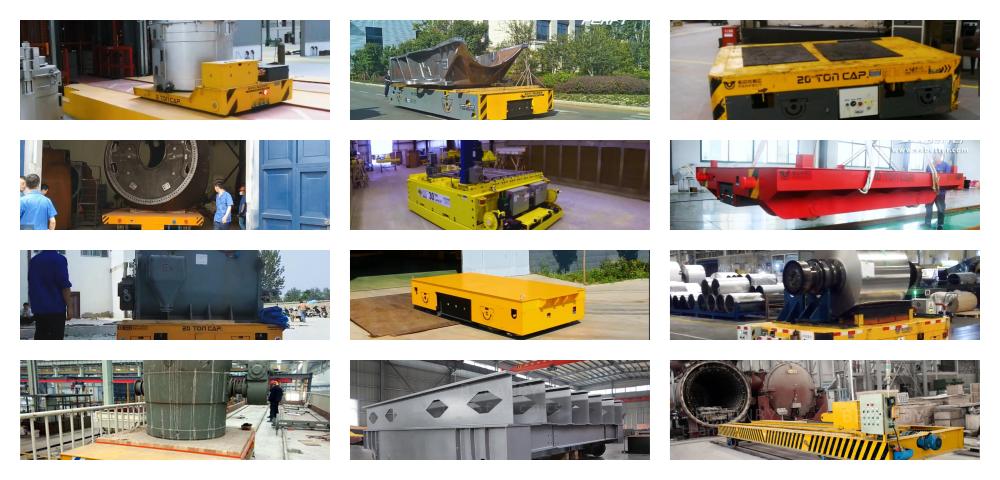

Materials handling: Mold, die, casting, Ingot, alloys, steel ladle, steel coil, steel pipe, steel billets, tooling and equipment and other foundry parts.

Introduction Of Foundry Parts Transfer Trolleys

Industrial transfer trolleys are specially crafted for the conveyance of heavy loads or machinery for the factory, whether it be indoors or outdoors. PERFECT provides an extensive array of transfer trolleys designed for handling molds and foundry parts, tailored to the distinct requirements of stamping, forming, and moving molds from storage to the stamping line. These mold transfer vehicles find widespread application in processes such as punching, pouring, cold heading, extrusion, powder metallurgy parts pressing, pressure casting, compression molding, or injection molding of engineering plastics, rubber, ceramics, and various other products. The flexibility of our mold transport solutions allows them to operate seamlessly on either rails or concrete floors, offering adaptability based on your specific requirements. If uncertain about the most suitable transfer vehicle for your needs, a brief discussion about your application’s requirements now can lead to future budget savings.

Customization of Foundry Parts Rail Transfer Trolley

- Capacity ranges from 1 ton to 500 tons

- Custom-shaped dimensions and color of trolley

- Battery power supply

- Lifting device available

- Push-pull operation or fully motorized

- Fully steering or controlled direction of movement

- Can be designed to run on rails or directly from the floor

- PLC system, remote control or fixed pendant

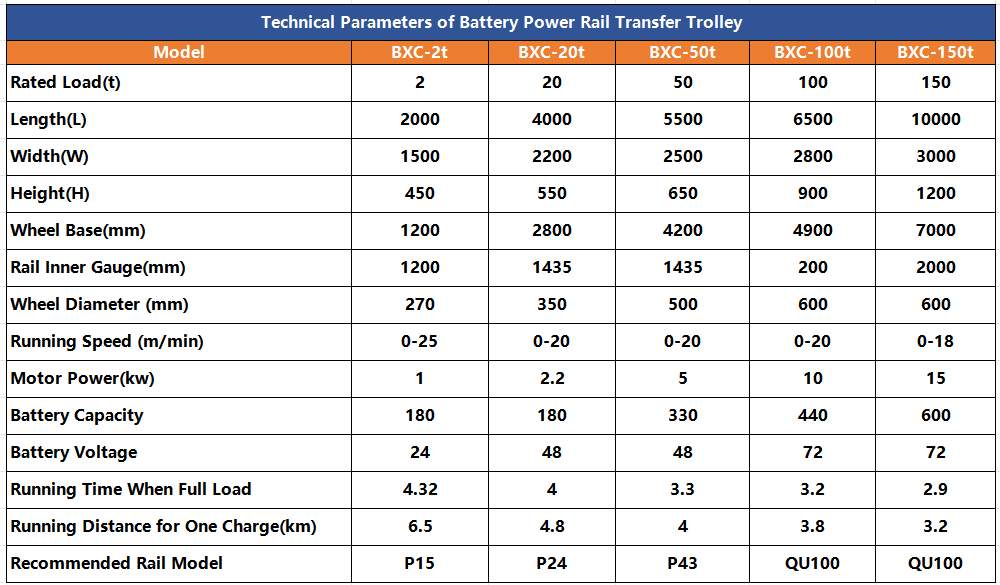

Parameters of Battery Power Rail Transfer Trolley

Accessories of Battery Power Rail Transfer Trolley

Precision Manufacturing for Production Process

Other Industrial Transfer Trolleys

Packaging & Shipping

Electric transfer vehicle is securely packed with tarpaulin, while its wheels and components are carefully enclosed in wooden boxes. For shipments with a length under 5.9m and a width under 2.2m, a 20-foot container is utilized. If the length exceeds 5.9m but is less than 12m, a 40ft container is employed. Full container shipping is feasible for 2 or 3 sets, whereas LCL (Less than Container Load) is suitable for a single set. If the length is under 12m but the width surpasses 2.2m, an FR container (20 or 40 feet) is required. Electric transfer vehicles exceeding these dimensions necessitate BB containers, with box size and material determined by the product’s shape and quantity.

Electric Transfer Trolley Supplier

PERFECT Material Handling Equipment stands at the forefront of machinery manufacturing in China with a workforce exceeding 200 employees, including 15 senior engineers, 20 engineers, and 25 technicians. 4 production lines and there are more 2600 units annual output. We maintain a year-round collaboration with the Nanjing Institute of Technology, where senior welding engineers provide hands-on guidance in production. Our commitment to quality is evident through our ISO9001 certification, along with CE, SASO, and SGS certificates. Additionally, we hold 8 national patents covering a range of innovations, including rail turning trolley utility model patent, S type rail turning appearance patent, rail electric forklift utility patent, electric rail tractor utility patent, steerable motorized electric transfer trolley utility patent, lifting electric trolley utility patent, scissor hydraulic lifting electric trolley patent, whole ring rail electric trolley’s wheel and transfer trolley patent.

Our Services

- Our pledge: Motorized transfer trolleys guarantee a load-bearing safety factor of not less than 120%.

- You can get complimentary design services for auxiliary devices or basic drawings, along with the provision of technical support and drawing materials.

- You benefit from 16-hour engineering services and 24-hour online support.

- During the warranty period, if issues arise with our electric pallet truck, we provide free repair technology or replacement of related parts within 24 hours.

- Quality concerns are addressed within 24 hours, demonstrating our unwavering commitment and a serious approach from start to finish. We highly value our reputation and diligently uphold the image of our company.

you can contact us in the following ways.

-

40 ton rail transfer trolley for train carriage, is used for turning and positioning railway locomotives, comprehensively solve the technical problem of changing the operating direction of transfer trolley.

Model: BXC

Load capacity: 40ton

Power supply: Battery power

Continuous working hours: 6-8 hours

Running speed: 1-20m/min adjustable

OEM: Support

Warranty: 2 years -

Battery operated rail turntable transfer trolley is an industrial material handling vehicle designed for the movement and transportation of heavy loads within a manufacturing or warehouse environment.

Warranty: 2 Years

Capacity: 1-1.500 tons

Certificate: CE SGS, lS09001

OEM: Support

Quality Assurance: All transfer trolleys are produced by supporting traceability of raw materials; Quality control is conducted on all production lines; Random inspection.

Competitive Price: Factory price with sustainable and environmental solutions. -

Heavy duty customized die transfer trolley 20t boasts a robust design tailored to meet special dimensions and material handling requirements. With state-of-the-art control systems, safety features, and operability options, our mold transfer trolleys ensure workers’ and equipment safety. Contact us to choose a power source that matches your facility’s infrastructure and experiences the durability of a structure built to withstand harsh working environments.

-

Electric transfer carts on rails for motor driven foundry industry applications are powered by battery. The battery is installed inside the cart. The main reason for using battery power is to consider long-distance transportation.

Load capacity: 1-500t customized

Dimension: Can be customized

Power supply: Battery/Cable/Busbar/Rail optional

Control system: PLC system, remote control or fixed pendant

Running speed:20-30m/min

Materials handling: Mold, die, casting, Ingot, alloys, steel ladle, steel coil, steel pipe, steel billets, tooling and equipment and other foundry parts.