Main Feature:

Model: BXC

Warranty: 2 years

Capacity load: 1-500T

Table size: Customized

Power supply: Battery Power

Working time: 6-8h (Continuous)

Introduction

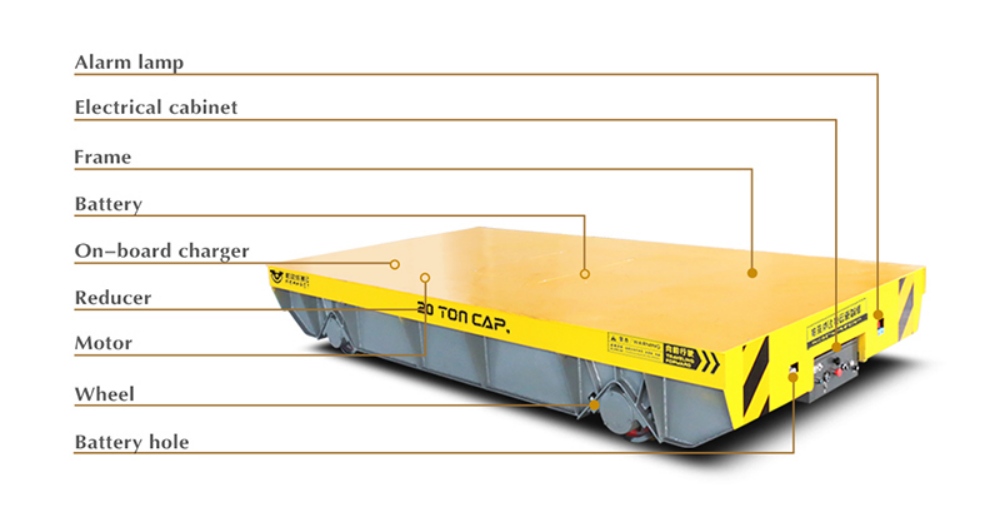

Battery powered transfer carts have two types, one is a battery rail transfer cart (Model is BXC), and the other is battery powered trackless transfer cart (Model is BWP). Heavy-duty battery-powered transfer vehicle is composed of batteries and is the power source for a series of flatbed vehicles. It powers the flatbed truck. The direct current flows into the distribution box and supplies the distribution box to the operating system and the motor.

Working Principle

Heavy load battery powered rail transfer vehicle is made up of the battery as the power source of the series of flat cars. It supplies power to the flat car. The DC flows into the electric box, and the electric box is supplied to the operating system and the motor. The control unit or the remote control controls the motor. Reverse, stop, etc., and then control the forward, backward, start, and stop of the flat car.

Feature of Battery Power Transfer Cart

1. Capacity up to 1,500 tons (BXC)

2. Capacity up to 500 tons (BWP)

3. Battery type ( Free of maintenance battery/Lithium battery/explosion-proof battery/anti-high temperature battery)

4. Intelligent charger optional (Low noise, fast charging, automatic stop, extended battery life)

5. Low battery alarm device. When the battery power is too low, it will alarm.

6. 4 hours charging time

7. Continuous working 8 hours

8. Times of charge and discharge over 10.008.

9. Sturdy frame. It adopts a box beam structure and does not deform.

10. DC motor with brush and DC motor brushless

11. Optional operation system (remote radio control/hand pendant/cabin/ PLC)

12. Customized functions: RGV control, lifting table, turning, weighing system, titling, climbing, traversing, roller support, waterproof treatment, ultra-low table, traverse unit, anti-rollover.

Applications of Heavy Load Battery Power Transfer Cart

- Mold workshop

- Coils and dies industry

- Foundry industry

- Steel industry

- Underground mine

- Engineering

BXC 40T Rail Transfer Cart from our Client Video

Advantage of Heavy load battery powered transfer vehicle

- Heavy load battery powered transfer vehicle has safety and maneuverability, the operation is not limited by distance, the speed is adjustable, and the flat-car DC motor has the advantages of stable starting, large starting torque, small impact on the reducer, low voltage, and long service life. The requirements for track laying are not high, and it is suitable for occasions with low frequency and long distance transportation.

- Heavy load battery powered transfer vehicle adopts a DC motor, which is suitable for frequent use and has higher safety and maneuverability. It can meet the transportation environment with a high frequency of use and can be equipped with a hard-tooth surface reducer, which makes the maintenance of cart later simple.

- Heavy load battery powered transfer vehicle is relatively simple, easy to repair, easy to disassemble, has strong carrying capacity, long service life, low requirements for track laying, low cost, and suitable for harsh environments, high-temperature environments, and other occasions.

- Battery operated motorized material transfer carts on rail are suitable for various use environments, and can work in indoor, outdoor, inflammable, and explosive environments, and can also add hydraulic devices, buffer devices, etc. on the flat car. The operation is simple. When the transportation distance is long, the onboard operation console can be added to the flat car to meet the long-distance transportation of the customer and realize the humanized design.

- Heavy load battery powered transfer vehicle can add a PLC control system, and the automatic rail car greatly increases work efficiency.

Battery Powered Rail Transfer Cart Parameters

| 1 | Load capacity(t) | 1-500 |

| 2 | Maximum impact load(t) | – |

| 3 | Size specifications(mm) | (Customized) |

| 4 | Table height(mm) | Customized |

| 5 | Two-wheel track(mm) | – |

| 6 | Power supply mode | Lithium battery or battery |

| 7 | Operating mode | Car handle or remote control |

| 8 | Drive mode | Motor driven |

| 9 | Brake method | Mechanical + automatic brake |

| 10 | Running speed(km/h) | 0-30(Adjustable speed) |

| 11 | Running noise | ≤70db |

| 12 | Wheel diameter(mm) | – |

| 13 | Continuous running time | 4-6h |

| 14 | Stationary state | Will lock, unlock |

Battery Powered Trackless Transfer Cart Parameters

| Model | BWP-5T | BWP-10T | BWP-15T | BWP-20T | BWP-30T | BWP-30T | BWP-50T |

| Impacted rated load (T) | 7.5 | 15 | 22.5 | 30 | 45 | 60 | 75 |

| Structure of frame | Steel plates welded, beam structure | ||||||

| Thickness of steel plate | 8 | 10 | 12 | 14 | 14 | 16 | 16 |

| Cart weight(T) | 4.3 | 5.3 | 6.6 | 7.9 | 8.8 | 10 | 10.5 |

| Max wheel load(T) | 2.8 | 4.6 | 4.3 | 5.6 | 7.7 | 10 | 12 |

| Table size (mm) | 3000×2000 | 3600×2000 | 4000×2200 | 4500×2200 | 5000×2200 | 5500×2300 | 6000×2300 |

| Height of the whole cart(mm) | 450 | 530 | 600 | 600 | 650 | 700 | 700 |

| Ground Clearance (mm) | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Wheels base (mm) | 1500 | 1500 | 1700 | 1700 | 1700 | 1800 | 1800 |

| Axles distance(mm) | 2500 | 3100 | 3400 | 3900 | 4300 | 4800 | 5200 |

| Turning radius(mm) | 2501 | 3101 | 3401 | 3901 | 4301 | 4801 | 5201 |

| Turning type | Turning while driving with no stop | ||||||

| Battery maintaince | Free of maintainance | ||||||

| Radar control | 3-0.3m Automatic stop for obstacles | ||||||

Battery Powered Rail Transfer Cart Price

Rail transfer cart can be configured with additional functional customization, such as climbing, anti-rollover, ultra-low table, hydraulic lift, shaft, robot arm, roller support, V-shape frame, U-shape frame, etc. Different types of transfer trolleys have different prices. Generally speaking, the price is cheap without additional functions, and the hydraulic pressure or long-term continuous work is slightly more expensive. You can configure it according to the actual material handling solution.

Why Choose Us?

Frame: We adopt the Box beam type structure of the transfer After annealing treatment, the cart frame is not easily out of shape, making the safety factor over 150%.

Welding: Without trachoma and seams. The weld surface is beautifully formed, uniform, and smooth.

Sandblasting and rush prevention: Sandblasting is waterproof and rustproof.

Motor: Low speed and large power running, stable starting, smooth driving large driving torque, light large loading driven by reducer directly. Low voltage, long service life, small volume, lightweight.

Reducer: Using transfer cart specialized hardened surface gear reducer. which is transmission efficiency, stable operation, low noise, easy installation and maintenance, and flexible shaft rotation at all levels.

Wheels: Polyurethane solid wheels for the BWP series transfer cart. These kinds of wheels are sturdy, and firm and do no damage to the ground.

Battery charger: Intelligent battery charging, charging after the completion of automatic alarm, simple and convenient operation.

Packaging & Shipping

Transfer Carts Factory from Perfect Supplier

Henan Perfect Metrail Handling Equipment Co.,ltd. is a material handling machinery manufacturing enterprise integrated into scientific research, production, and marketing. As the leading mechanical equipment manufacturer, we have aimed to become a first-class corporation producing material handling equipment since our founding day, till now, we have formed a complete production chain. With high-quality production and humanization management, Our company people swear to change the world’s opinion towards the Chinese manufacturing industry. now you can find our products in more than 60 countries all over the world, such as Russia, Germany, America, Australia, Singapore, Malaysia, Turkey, the Middle East, etc.

Our service:

Engineers provide professional technical support and create the perfect material handling solutions for you.

Before sale: Free scheme- Fast delivery-Flexible payment-Free reception

After-sale: Low failure rate- Free part replacement- 2 years warranty-Engineer available overseas

you can contact us in the following ways.

-

40 ton rail transfer trolley for train carriage, is used for turning and positioning railway locomotives, comprehensively solve the technical problem of changing the operating direction of transfer trolley.

Model: BXC

Load capacity: 40ton

Power supply: Battery power

Continuous working hours: 6-8 hours

Running speed: 1-20m/min adjustable

OEM: Support

Warranty: 2 years -

Battery operated rail turntable transfer trolley is an industrial material handling vehicle designed for the movement and transportation of heavy loads within a manufacturing or warehouse environment.

Warranty: 2 Years

Capacity: 1-1.500 tons

Certificate: CE SGS, lS09001

OEM: Support

Quality Assurance: All transfer trolleys are produced by supporting traceability of raw materials; Quality control is conducted on all production lines; Random inspection.

Competitive Price: Factory price with sustainable and environmental solutions. -

Heavy duty customized die transfer trolley 20t boasts a robust design tailored to meet special dimensions and material handling requirements. With state-of-the-art control systems, safety features, and operability options, our mold transfer trolleys ensure workers’ and equipment safety. Contact us to choose a power source that matches your facility’s infrastructure and experiences the durability of a structure built to withstand harsh working environments.

-

Electric transfer carts on rails for motor driven foundry industry applications are powered by battery. The battery is installed inside the cart. The main reason for using battery power is to consider long-distance transportation.

Load capacity: 1-500t customized

Dimension: Can be customized

Power supply: Battery/Cable/Busbar/Rail optional

Control system: PLC system, remote control or fixed pendant

Running speed:20-30m/min

Materials handling: Mold, die, casting, Ingot, alloys, steel ladle, steel coil, steel pipe, steel billets, tooling and equipment and other foundry parts.